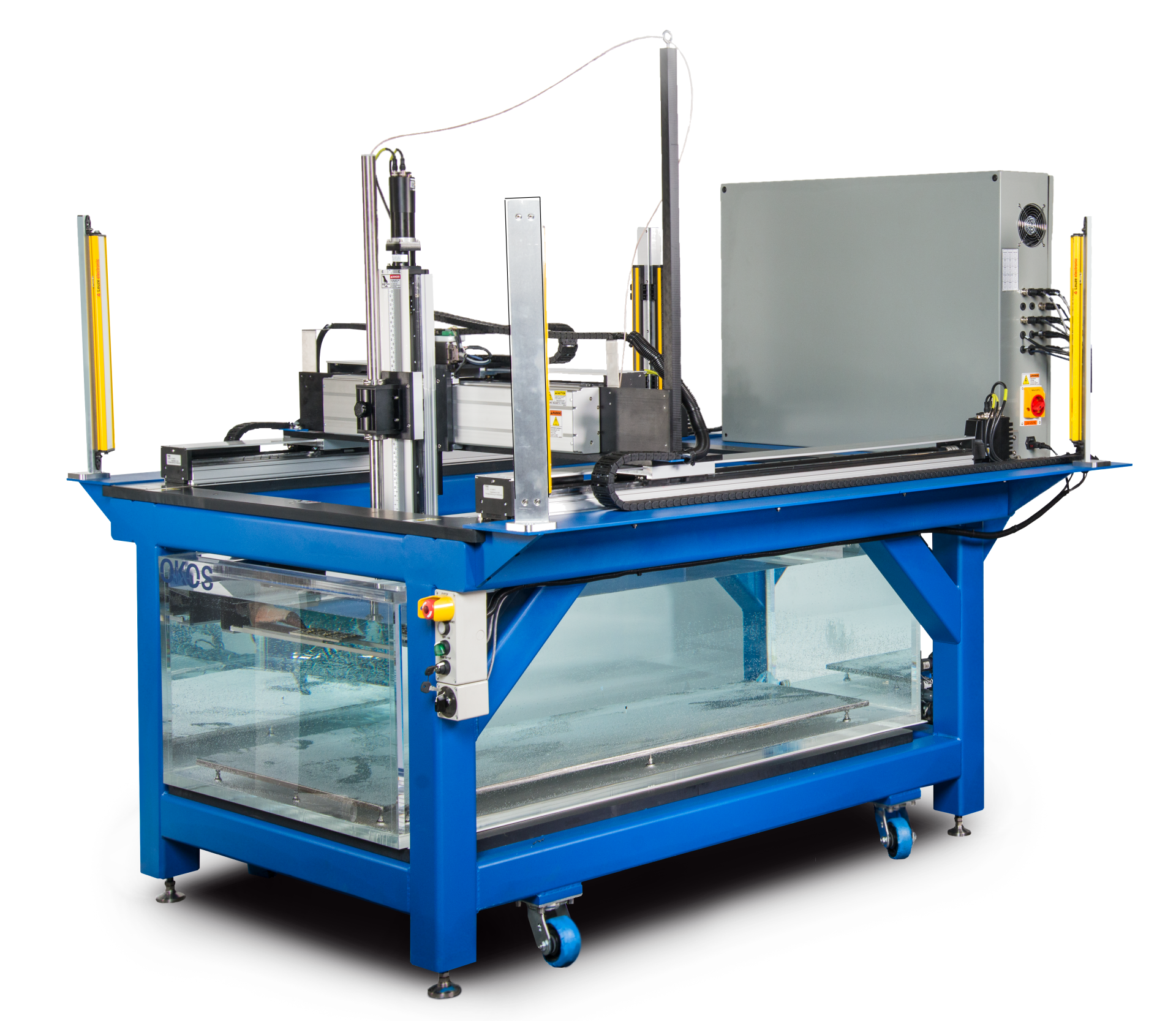

Multi Axis Industrial UT NDT

Scanner with dual Z

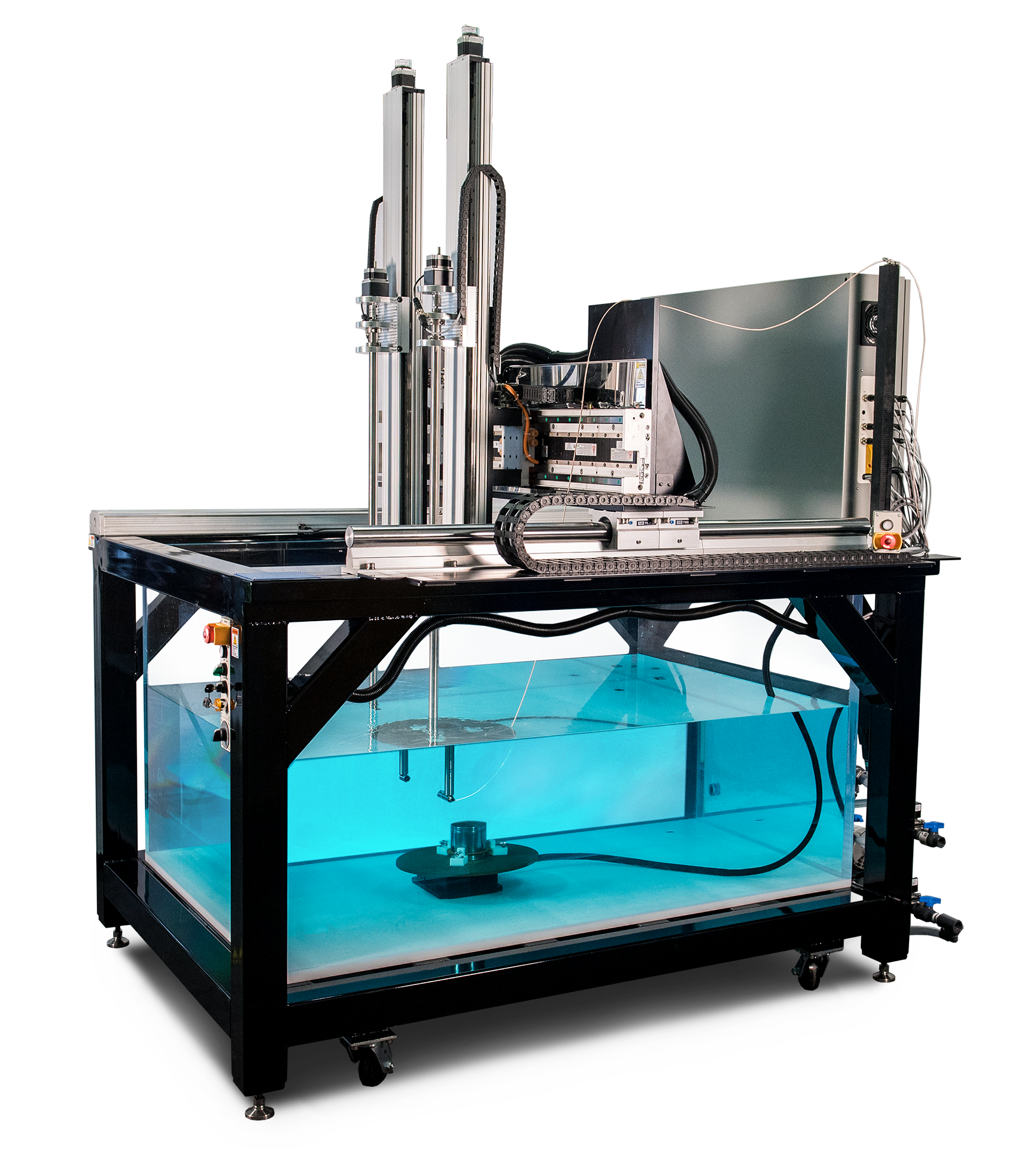

5 Axis Compact NDT Scanner

(Research & Universities)

Ultrasonic NDT Systems

Industrial Ultrasonic Non-Destructive Testing Systems (UT-NDT) designed by OKOS

Industrial Ultrasonic Non-Destructive Testing (UT-NDT) has been around for decades. OKOS products apply to Industrial UT-NDT, newer technologies and solutions designed and developed for Scanning Acoustic Microscopy marketplace. Inspectors look for 1000 micron (1 mm) defects in metals, as this was the norm. With new technologies, defects as small as 20 microns can be identified in metals and alloys.

What is non-destructive testing (NDT)?

When inspecting samples there are two methods of testing, destructive testing, and non-destructive testing. With destructive testing methods such as cross sectioning the sample is usually discarded afterwards and is unable to be used again. Additionally, when performing a destructive test, defects can be introduced into the sample that were not originally present. This is where non-destructive testing provides the biggest advantages.

Why Use Ultrasonic Nondestructive Testing?

With non-destructive testing the internal layers of a sample can be viewed without altering the sample from its current state. This is useful in situations where performing a destructive test on a sample is not economically viable or in cases where the sample is fragile enough that any kind of destructive test would introduce additional defects which were not originally present resulting in possible false positive detection of defects. Using SAM users can also rapidly inspect various aspects of a sample such warpage, voids, delaminations, and density changes simultaneously on multiple layers/interfaces.

NDT System (Non-Destructive Testing) are also used to scan and analyze parts via ultrasound. While SAM system are a specialized version of an NDT system using only three axes. NDT systems can come with anywhere from 2 to 12 axes, depending on the type of part to analyze. NDT systems often include rotators/turntables and Gimbal/Swivel mechanisms, allowing them to perform complex motions in order to scan. NDT systems are very useful in industry in order to test larger and irregularly shaped parts, such as cones, curves, cylindrical and angled parts.